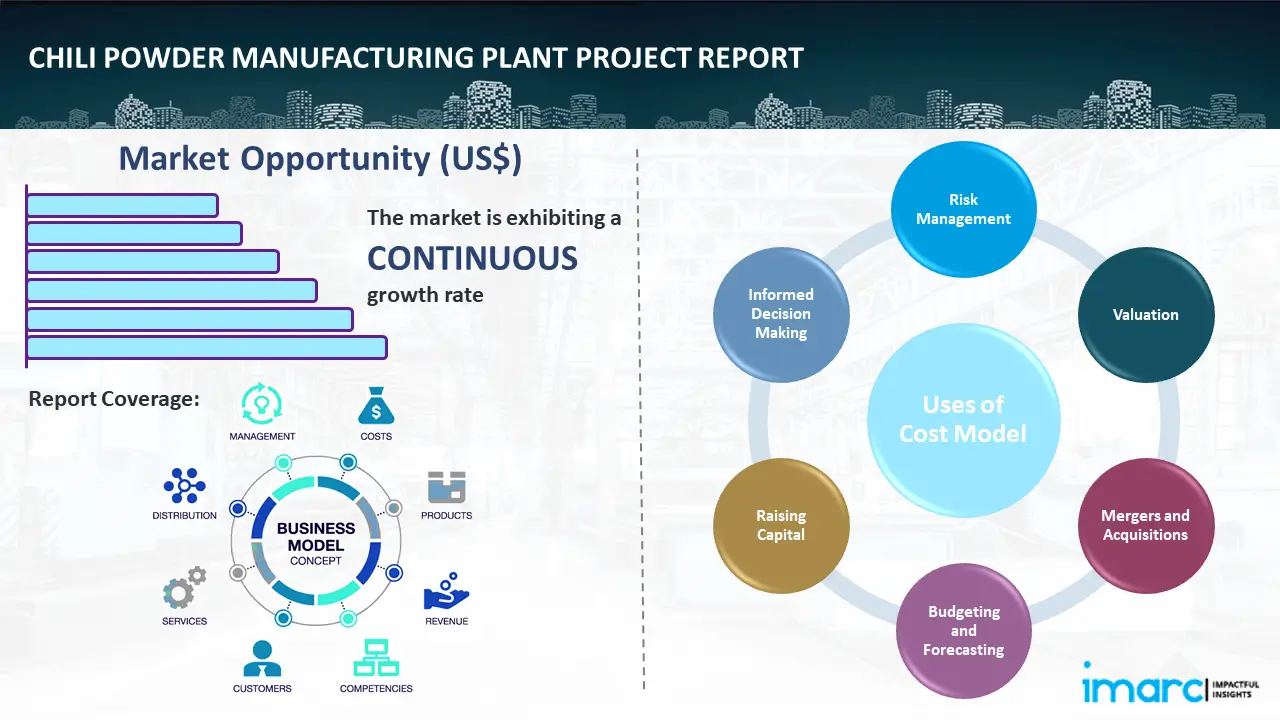

IMARC Group’s report, titled “Chili Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides a complete roadmap for setting up a chili powder manufacturing plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc. The report also provides detailed insights into project economics, including capital investments, project funding, operating expenses, income and expenditure projections, fixed costs vs. variable costs, direct and indirect costs, expected ROI and net present value (NPV), profit and loss account, financial analysis, etc.

Chili powder is manufactured by grinding dried and pulverized red chili fruits from one or more varieties of chili pepper. It is primarily used to add flavor and heat to culinary dishes and is a common ingredient in American, Indian, Mexican, and other cuisines. The degree of spiciness of chili powder varies from mild to moderate, based on the quantity of cayenne pepper in the mixture. In addition to enhancing the taste and color of dishes, chili powder also acts as a good source of vitamin C, which is an antioxidant and helps strengthen the immune system. Despite its low-calorie count, it assists in supporting the digestive system. It is a nutrient-dense spice, rich in various vitamins, minerals, and proteins (amino acids), essential for maintaining good health. It also contains beneficial phytochemicals, such as alkaloids (capsaicin), flavonoids, and phenolics, which are potent antioxidants.

Chili powder is widely used in pharmaceutical, cosmetics, and personal care industries due to its excellent capsaicin content, the primary bioactive compound that possesses pain-relieving, anti-bacterial, and anti-inflammatory properties. Moreover, the rising consumption of chili powder owing to shifting consumer preferences toward spicy food and increasing willingness to try out new cuisines and exotic foods is positively influencing the market growth. Along with this, the increasing demand for organic chili powder due to shifting consumer inclination toward organic products is propelling market growth. Additionally, the escalating demand for exotic and spicy oriental dishes owing to the rising number of tourists traveling to Asian countries has catalyzed market growth. Besides this, the growing popularity of restaurant foods and cuisine and the increasing consumer preference for flavored foods have augmented the demand for chili powder. Furthermore, several favorable initiatives taken by governments of numerous countries to supply farm inputs, such as seeds, fertilizers, agricultural machinery & equipment, and irrigation facilities at subsidized rates to the farmers, are contributing to the market growth. Other factors, including rapid expansion in the pharmaceutical and cosmetics sectors, inflating consumer disposable incomes, and emerging food truck culture, are also anticipated to create a positive market outlook.

The following aspects have been covered in the report on setting up a chili powder manufacturing plant:

The report provides insights into the landscape of the chili powder industry at the global level. The report also provides a segment-wise and region-wise breakup of the global chili powder industry. Additionally, it also provides the price analysis of feedstocks used in the manufacturing of chili powder, along with the industry profit margins.

The report also provides detailed information related to the process flow and various unit operations involved in a chili powder manufacturing plant. Furthermore, information related to mass balance and raw material requirements has also been provided in the report with a list of necessary quality assurance criteria and technical tests.

The report provides a detailed location analysis covering insights into the land location, selection criteria, location significance, environmental impact, and expenditure for setting up a chili powder manufacturing plant. Additionally, the report provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

The report also covers a detailed analysis of the project economics for setting up a chili powder manufacturing plant. This includes the analysis and detailed understanding of capital expenditure (CapEx), operating expenditure (OpEx), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis. Furthermore, the report also provides a detailed analysis of the regulatory procedures and approvals, information related to financial assistance, along with a comprehensive list of certifications required for setting up a chili powder manufacturing plant.

| Report Features | Details |

|---|---|

| Product Name | Chili Powder |

| Report Coverage | Detailed Process Flow: Unit Operations Involved, Quality Assurance Criteria, Technical Tests, Mass Balance, and Raw Material Requirements |

Land, Location and Site Development: Selection Criteria and Significance, Location Analysis, Project Planning and Phasing of Development, Environmental Impact, Land Requirement and Costs

Plant Layout: Importance and Essentials, Layout, Factors Influencing Layout

Plant Machinery: Machinery Requirements, Machinery Costs, Machinery Suppliers (Provided on Request)

Raw Materials: Raw Material Requirements, Raw Material Details and Procurement, Raw Material Costs, Raw Material Suppliers (Provided on Request)

Packaging: Packaging Requirements, Packaging Material Details and Procurement, Packaging Costs, Packaging Material Suppliers (Provided on Request)

Other Requirements and Costs: Transportation Requirements and Costs, Utility Requirements and Costs, Energy Requirements and Costs, Water Requirements and Costs, Human Resource Requirements and Costs

Project Economics: Capital Costs, Techno-Economic Parameters, Income Projections, Expenditure Projections, Product Pricing and Margins, Taxation, Depreciation

Financial Analysis: Liquidity Analysis, Profitability Analysis, Payback Period, Net Present Value, Internal Rate of Return, Profit and Loss Account, Uncertainty Analysis, Sensitivity Analysis, Economic Analysis

While we have aimed to create an all-encompassing report, we acknowledge that individual stakeholders may have unique demands. Thus, we offer customized report options that cater to your specific requirements. Our consultants are available to discuss your business requirements, and we can tailor the report's scope accordingly. Some of the common customizations that we are frequently requested to make by our clients include: